Polyester

Polyester

is a special type of polymer that contains the ester functional group in the

main chain. It is a specific material, it refers to a type called polyethylene

terephthalate (PET). It contains naturally occurring chemicals such as tree

cuttings, as well as synthetics such as polybutyrate. Natural polyesters and a

few synthetics are biodegradable, but most synthetic polyesters are not. Polyester material is widely used in clothing.

It

is sometimes combined with natural fibers to create a fabric with blended

properties. Cotton-polyester blends must be strong, wrinkle, and tear-resistant

and reduce shrinkage. Man-made or synthetic fibers using polyester have higher

water, wind, and environmental resistance than fibers obtained from plants.

These are less fire-resistant and can melt when ignited.

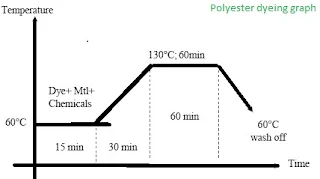

Polyester dyeing process

In

the polyester dyeing process, scattered dyed polyester fibers can be considered

as a dye transfer process from liquid solvents like water to solid organic

solvents like fiber.

When

dyeing polyester, the scattered dyes are added to the water with a

surface-activating agent for an aqueous dispersion. The invisibility of

scattered pigments enables them to give up dye alcohols because they are more

numerous than organic fibers than inorganic dyed alcohols. With the application of

pigment heat (130 to 135 °C), alcohol increases the strength of the pigment

molecule and accelerates the dyeing color of polyester fibers. Heating the

pigment alcohol causes some amount of polyester fiber to swell and helps the

dye to enter the polyester polymer system.

Thus

the dye molecule takes place in the amorphous regions of the polyester fiber.

Once the polyester has taken place in the polymer system, the dye molecules are

held by the hydrogen bond and the van der Waals force.

The dye is taken in the following simultaneous steps: Isolation of individual

molecules into the water to disperse the dye at a solid level. This expansion

depends on the dispersion and solubility of the dyestuff and is aided by the

presence of dispersing agents and rising temperatures.

Synthesis

of dissolved dyes from polyester surface solutions. This dyestuff addition to

the polyester surface is influenced by the solubility of the dye bath dyes and

the polyester fiber. The splitting of the assorted dye from the surface of the

fiber inside the fibrous material towards the center. Under normal

circumstances, the rate of absorption is always higher than the rate of spread.

And it’s a step in managing polyester dyeing.

Recipe for polyester dyeing-

Dyestuff – 2%

(20-30g/liter) on the weight of the material

Carrier – 12 to 15g/liter

Dispersing Agent – 2 to 3g/liter

Acetic Acid – (Adding till pH-4)

Material: Liquor Ratio – 1:20

Temp – 130 °C

Carrier – 12 to 15g/liter

Dispersing Agent – 2 to 3g/liter

Acetic Acid – (Adding till pH-4)

Material: Liquor Ratio – 1:20

Temp – 130 °C

0 Comments