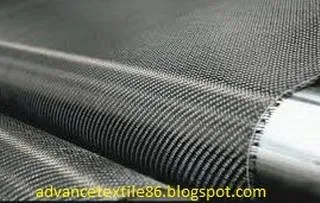

Carbon fibers

Carbon fibers consist of fibers

about 5-10 micrometers in diameter and mostly carbon atoms. It has

various advantages including higher hardness, high tensile strength, low

weight, high chemical resistance, high-temperature tolerance, and low thermal

expansion. These features have made carbon fiber very popular in aerospace,

civil engineering, military, and motorsports, among other competitive sports.

However, these are relatively expensive when compared with similar fibers such

as glass fibers or plastic fibers.

Properties of Carbon fiber

1. Carbon fiber is a composite

fiber.

2. It has reinforcement properties,

which provide strength.

3. Reinforcement gives the Carbon

fiber respectively high strength and rigidity.

4. It has directional strength

properties.

5. It has high tensile strength and

stiffness.

6. It has low weight and thermal

expansion.

7. It has high chemical resistance

and temperature tolerance.

8. The atomic structure of carbon

fiber is similar to graphite.

Preparation of Carbon fibers

To make carbon fiber, the carbon

atoms are bound together in crystals that are more or less aligned parallel to

the long axis of the fiber because crystal alignment gives the fiber a volume

ratio of high strength. Thousands of carbon fibers are bundled together to

form a tow that can be used manually or woven into a fabric. Each carbon

filament is made from a polymer such as a polyacrylonitrile (PAN), rayon, or

petroleum pitch. A common method of production involves heating the span of PAN

filaments in the air at about 300 °C, which breaks many of the hydrogen bonds

and forges the material. The oxidized PAN is then placed in a furnace with an

inert atmosphere of gas like argon and heated to about 2000 °C, which alters

the structure of the molecular bond and induces graphitization of the material.

When heated under the right conditions, these chains bind side-by-side, forming

narrow graphene sheets that eventually merge into a single, and columnar

filament structure. The result is usually 93-95% carbon. Low-quality fibers can

be made using pitch or rayon as a prefix instead of PAN. Carbon can be further

enhanced by the heat treatment process as high modulus or high strength carbon.

Carbon heated in the range of 1500-2000 °C exhibits a maximum tensile strength

of 5,650 MPa, while heated carbon fibers from 2500 to 3000 °C exhibit a higher

modulus of elasticity.

Uses of Carbon fiber

1. Carbon fiber filament yarns are

used in a variety of processing techniques: direct use for precipitation,

filament winding, poultry, weaving, braiding, etc.

2. It is used for the fabrication

of carbon-fiber microelectrodes.

3. Carbon fiber is most notably

used to reinforce composite materials,

4. It is used as an aerospace

application.

5. It can be used as an additive to

asphalt to make electrically-conductive asphalt concrete.

6. When woven into large fabrics,

they can be used to provide reliable infrared heating in applicable fields that

require flexible heating elements and can easily hold temperatures up to 100 °C

due to their physical properties.

0 Comments