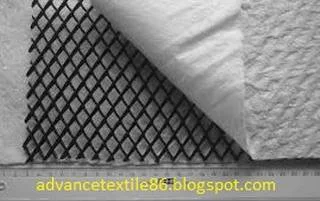

Nonwoven fabric

Nonwoven

fabric is a fabric component that is produced from staple and long fibers,

bound together by chemical, mechanical, thermal, or solvent treatment. Used to

denote what is not woven or woven as felt in the textile manufacturing

industry. Some molecules of woven material lack sufficient strength unless

solidified or strengthened by support. In recent years, nonwovens have been used

instead of polyurethane foam.

History

In the nineteenth century, when England was a leading country in textile

production, a textile engineer named Garnett realized that a large amount of

fiber was wasted as a trim, so he developed a special carding device to

distribute this waste material in fibrous form. This fiber was used as a

filling material for pillows. Although the Garnett machine has changed greatly,

it still retains its name and is a major component of the nonwoven industry.

Later, manufacturers in northern England began tying these fibers mechanically

and chemically to batts. These were the precursors of today's nonwovens. An

exploration of the nonwoven fabric industry began in the late 1940s,

which entered a commercial phase in the 1950s and then expanded commercially in

the 1960s.

Properties of nonwoven fabric

1.

Non-woven fabrics can look like paper, felt, or woven fabrics.

2.

Its hand-feel may be soft, elastic, or maybe hard, stiff, or slightly elastic.

3.

It can be as thin or many times thick as tissue paper.

4.

It can be transparent or opaque.

5.

It can be a low tear and blast energy to very high tensile strength.

6.

It can be fabricated by gluing, heat bonding, or sewing.

7.

The drapability of this type of fabric is not much different from good.

8.

Some fabrics have excellent laundry; Nothing else.

9.

Some may be dry-cleaned possible.

10.

It provides specific works such as absorbency, strength, flame retardancy,

washability, cushion, fluid repellent, elasticity, stretch, softness, thermal

insulation, acoustic insulation, filtration, bacterial barrier, and germs.

Types of nonwoven fabric

The

main and most common types of non-woven fabrics are:

1.

Spun-bound/Spun-lace.

2.

Air-laid.

3.

Dry-laid.

4.

Wet-laid.

Spun-bound: Span-bound fabrics are produced by

binding fibers in an album method by depositing extruded, spun filaments in the

collection belt. The fibers are separated at the time of laying process on the

web by air jets or electrostatic charges. Spun-bound

products are used in carpet backing, geotextile, disposable medical /

hygiene products, automotive products, civil engineering, and packaging

products.

Air-laid: Air-laid fabric is mainly made with

wood pulp and has good absorption nature. It can be mixed with a certain

proportion of sap to improve its wet absorption capacity. Air-laid nonwoven dry

paper is also referred to as nonwoven. Nonwoven is made through the process of

an air bed. Transfer the wood pulp to an airflow bundle to spread and

consolidate the fibers on the floating web. The Air-laid non-woven bonnet is

reinforced on the web.

Dry-laid: Dry laid webs are simply produced using

staple fibers natural or manmade. Dry laid webs making process consists of 4

steps:

Staple

fiber preparation –> Opening, cleaning, mixing & blending –> Carding

–> Web laying.

Wet-laid: wet-laid non-woven fabric is made by a

modified papermaking process. That is, the fibers used are suspended in water.

One of the main goals of wet-laid nonwoven manufacturing is to produce

textile-fabric characteristic structures, primarily flexibility and strength,

at the speed of those involved in making paper. Special paper machines are used

to make uniform sheets of material to separate water from the fibers, which are

then bonded and dried. In the roll, good industrial 5-10% nonwovens are made

using wet-leveled technology.

The non-woven fabric production process

Nonwoven

fabric production can be described in simple terms as a series of integrated

production steps to wrap or bind the fibers on the web to maintain mechanical

integrity in the structure and to give the fabric some special features.

1. Web formation

The

properties of the fibrous web are the key determinants of the physical

properties of the final product. The choice of method for forming webs is

determined by the length of the fiber. Primarily, the methods of forming mesh

from main length fibers were based on the textile carding process, whereas web

formation from short fibers was based on wetting the same kind of paper. These

technologies are still in use, but immediately Methods based on web structure

have also been developed. Fiber webs have little mechanical strength and

require a further manufacturing process to form a fabric with useful

properties. There are many processes that are used to perform this as described

in the next section.

2. Web bonding

Needle

punching is the process of bonding a nonwoven web structure that mechanically

connects fibers to the web. The cut needles, attached to a board, are retracted

by punching the fibers to the web and then the fibers. Since the needle board

is retractable, the needles are emptied in a non-aligned format.

i. Stitch bonding: Stitch bonding is a method of assembling

fiber gels with yarn components with or without yarn to attach the fibers.

Different types of yarn can be used. Upholstery is a market for these fabrics.

Other uses are vacuum bags, geotextiles, filtration, and interconnections. In many

applications, sewing-tied fabrics are replacing woven products because they are

faster to produce and therefore, the production cost is significantly lower.

ii. Thermal bonding: The process of stabilizing a web

structure with thermal bonding heaters or thermoplastic fibers. All parts of

the fibers act as heat binders, thus eliminating the use of latex or resin

binders. Thermal bonding is a major method used by the cover stock industry for

baby diapers. Polypropylene has become the most suitable fiber with a low

melting point of about 165C. It is also soft to the touch. The fiber web is

passed between the heated calender rollers, where the web is closed. In most

cases point binding using embossed rolls is the most preferred method, adding

softness and flexibility to the fabric. The use of smooth rolls increases

strength by binding the entire surface of the fabric but reduces grooves and

softness.

iii. Chemical bonding: Chemical bonding the process of web

bonding and bonding through a chemical is one of the most common methods.

Chemical binders are applied to the web and cured. The most used binder is

latex because it is economical, easy to apply, and very effective. Different

techniques are used to apply the binder and include saturation bonding, spray

bonding, print bonding, and foam bonding.

iv. Hydro entanglement: Hydro entanglement is the process of

using liquid energy to lock fibers together. This is achieved by fine water

jets operated through the web, supported by a conductive belt. The water gets

entangled when the web is attacked and the fibers are removed. Strong movement

fibers get involved in the web.

3. Finishing and

converting

Finished

and converted the last operation performed on the fabric before being delivered

to the customer. Finishes include some activities like coating and laminating

to change the wet properties of the fabric, coronation and plasma treatment,

wet chemical treatment to provide anti-static properties, anti-microbial

properties, flame retardant, etc. This is usually cut to width specifying a

rebound ready for customer shipment this is known as conversion.

Uses of nonwoven

1.

Nonwoven fabric is used in medical products like isolation gowns, surgical

gowns, masks, scrub suits, caps, gloves, plasters, etc.

2.

It is used as a filter for gasoline, oil, air, water, coffee, tea bags, the pharmaceutical industry, mineral processing, liquid cartridge, bag filters,

vacuum bags, etc.

3.

Its geotextile containers are used for soil stabilizers and roadway

underlayment, foundation stabilizers, erosion control, canals construction,

drainage systems, geomembrane protection, frost protection, pond, and canal

water barriers, sand infiltration barrier for drainage tile, landfill liners,

etc.

4.

It is used in making diaper stock, feminine hygiene, and other absorbent materials.

5.

It is used in carpet backing and primary and secondary composites.

6.

It is also used in marine sail laminates, table cover laminates, chopped strand

mats, shopping bags, acoustic insulation for appliances, automotive components,

and wall paneling.

7.

It is used in household products like pillows, cushions, mattress cores, upholstery padding, batting in quilts or comforters, etc.

0 Comments