E-textiles

Electronic textile is a fabric

that enables digital components like batteries and light and enables

electronics to be embedded in them. In other words, Smart Textile is a fabric that

is made with new technology that provides extra value to the wearer. Pratt Institute

scientist Piles-Friedman says that what makes smart fabrics attractive is that

they have the ability to do many things that textile fabrics can't do,

including communication, conversion, energy management, and even enhancement.

History of e-textile

The basic things needed to create e-textiles,

conductive threads, and fabrics have been about for over 1000 years. In

particular, artisans have for many centuries often covered gold and silver with

fine metal foils around fabric threads. Many of Queen Elizabeth I's first

gowns, for example, were embroidered with gold-plated yarn.

In the late 19th century, as people developed and

became accustomed to electronic devices, designers and engineers began

combining electricity with clothing and jewelry to develop a series of

illuminated and motorized necklaces, hats, brooches, and clothing. For example,

in the late 1800s, a person could hire a young lady dressed in light-dressed

evening gowns from an electronic girl lighting company to entertain a cocktail

party.

The first acquisition of a dozen patents based on

LED/optic displays and instruments in 1979, the first CNC machines in 1999 to

produce animated coats for Disney Park. Two additional smart fabric

technologies were unveiled by Wayne Wright at the Flextech Flexible Display

Conferences held at Phoenix, AZ, infrared digital displays embedded in the

machine embedded in the fabric for the IFF that were submitted to the BEF

Systems for evaluation in 2006. An honorable mention award from NASA in 2010 on

the "Design of the Future" contest.

Smart textiles

Smart textiles can be

divided into two separate categories: aesthetic and performance-enhancing.

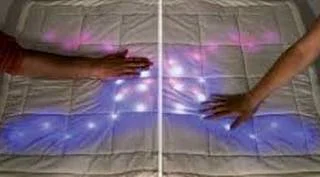

Aesthetic examples include fabrics that are illuminated and fabrics that can

change color. Some of these fabrics collect energy from the environment using

vibration, sound, or heat, responding to these inputs. The color-changing and

illumination scheme can work electronically by embedding the fabric which can

give it strength. Performance-increasing smart textiles are intended

for use in extreme sports, athletic, and military applications. These include

fabrics designed to control body temperature, reduce wind resistance, and

control muscle vibration - these can improve athletic performance. Other

fabrics are designed for protective clothing, such as to protect against

extreme environmental hazards such as the effects of radiation and space

travel. The health and beauty industries have also taken advantage of this

innovation, ranging from drugs to medical textiles to moisturizers, perfumes,

and fabrics with anti-aging properties. Much smart clothing, wearable

technologies, and wearable computing projects involve the use of e-textiles.

Smart textile production

Smart Textile Fabrics can

be made in traditional Kevlar with integrated functionality from traditional

cotton, polyester, and nylon. Currently, interested in fabrics with electrical

conductivity. Electrically conductive fabrics were produced through woven

fibers and metallic nanoparticle deposits around the fabric. The resulting

metallic fabrics have conductive, hydrophilic, and higher electrical regions.

These properties render them the ideal layer for electronic chemical

biosensing that was demonstrated with DNA and protein identification.

Smart medical textile

Two types of Smart medical textile products have been developed and studied for health monitoring: textile-based sensor electronics and fabric that envelop traditional sensor electronics. Smart textiles prove that a loom can be used to incorporate electrically conductive yarn with the fabric to get the textile to be used as a wearable motherboard. It can connect multiple sensor signals of the body to the acquisition electronics, such as the wet Gel ECG electrode. Studies have shown that conductive yarns can be helpful in weaving textile-based sensors coated with silver conductive metal cores that are woven into the fabric.

0 Comments