Nylon Fiber

Nylon is a common term for a family of synthetic polymers consisting of polyamide. Nylon is a silk-like thermoplastic, usually made from petroleum, which can be processed by dissolving in fiber, film, or shape. Nylon polymers can be blended with a variety of additives to achieve a variety of properties. Nylon polymers have found significant commercial applications in fabrics and fibers, shapes, and films.

Nylon

was the first commercially successful synthetic thermoplastic polymer. DuPont

began his research project in 1927. The first example of nylon, (Nylon 66), was

made using diamine on February 28, 1935, by Wallace Hume Carothers at DuPont's

Research Center at DuPont's Experimental Station. In response to Carothers'

work, IG Farbenne Paul Schlack created a different molecule, Nylon 6, on

January 29, 1938, based on Caprolactam.

Chemistry of nylon fiber

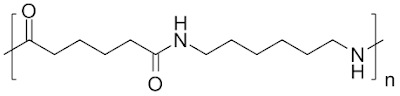

Nylon

is formed by the reaction of isolated monomers with short polymers or

copolymers, amines, and carboxylic acids in equal parts so that amides are

formed at both ends of each monomer in a process equivalent to a polypeptide

biopolymer. Most nylon is made from the reaction of dicarboxylic acids with

diamine (e.g. PA66) or lactam or amino acids themselves (e.g. PA6). In the first case, the repeating units form one of each monomer, so that they are

alternated in chains like polyester and polyurethane ABAB structures that have

the overall direction: C Terminal → N Terminal. In the second case, the

repetition unit matches the single monomer.

Types of nylon fiber

There

are different types of nylon fiber as follows-

Nylon 66

Nylon

66 is a derivative of polyamide or nylon. It is most common in the textile and

plastic industries. Nylon 66 is collected from two monomers each containing 6

carbon atoms, hexamethylenediamine, and adipic acid that gives the name nylon

66. Nylon 66 is often used when high mechanical strength, good stability under

heat, rigidity, and chemical resistance is required. It is used in textiles and

fibers for carpets and welded parts. For textiles, these fibers are sold under

different brands, like Nilit brand or Cordura brand luggage, but it is also

used in airbags, clothing, and carpet fibers under the Ultron brand. Nylon 66

lends itself well to creating 3D structural objects by making injection molds.

It is used in automotive applications like hood parts such as radiators and

tanks, rocker covers, air intake manifolds, and oil pans, as well as other

structural parts like hinges and ball bearing cages. Other uses are

electro-insulating components, pipes, profiles, Includes zip ties, conveyor

belt, hose, polymer-framed arms, and outer layer of turnout blanket. Nylon 66

is popular for guitar nut material.

|

| Nylon 6,6 |

Nylon 6

Nylon

6 is a polymer that was developed to reproduce the properties of Nylon 6,6 without

violating the patent produced by Paul Slack at IG Farben. It is a

semicrystalline polyamide. Nylon 6 is not a condensing polymer in place of

other nylons, but it is produced by ring-opening polymerization. This makes it

a special case in terms of comparison between condensation and addition

polymers. It's challenging with Nylon 6,6 and the example it sets also shaped

the economy of the synthetic/artificial fiber industry. It is sold under

different trade names, like Perelon, Akulon, Dederon, Nilatron, Capron,

Ultramid, Capron, and Durethan.

|

| Nylon 6 |

Nylon

6 fibers contain stiffness, high tensile strength, as well as elasticity, and

luster. They are wrinkle-proof and abrasive and highly resistant to acids and

alkaline chemicals. Fibers can absorb up to 2.4% of water, although it reduces

tensile strength. The glass transfer temperature of nylon 6 is 47 °C. As a

synthetic fiber, nylon 6 is usually white but can be dyed in the solution bath

before production for different color results. With a density of 1.14 g / cm3,

its tensile strength is 6–8.5 gf / d. It has a melting point of 215 °C and can

withstand temperatures up to 150 ° C on average.

Nylon 510

The

Nylon 510 is created from pentamethylene diamine and sebacic acid, and it was

also studied by cards before the Nylon 66 and has superior properties but is

more costly to make. With this naming convention in mind, Nylon 6,12 or PA 612

is a copolymer of 6C diamine and 12C dioxide. For example, some fully scented

nylons are polymerized by adding dioxides such as terephthalic acid or

isophthalic acid which is usually associated with polyesters containing PA cop

66/6; Copolymers of PA 66/6/12; And others. Linear polymers are usually the

most effective, but it is possible to introduce nylon branches by the concentration of dicarboxylic acid with polyamines with three or more amino

groups.

Nylon 1,6

Nylon

1,6 is a version of polyamide or nylon. Unlike other nylons, nylon 1,6 is not a

concentration polymer but instead is composed of adiponitrile, formaldehyde,

and acid-catalytic synthesis from water. This material was produced and studied

by researchers at Dupont in the 1950s. Can be synthesized at room temperature

in open bakeries.

Nylon

1,6 is manufactured from adiponitrile, formaldehyde, and water through acid

catalysis. Adiponitrile and formaldehyde are associated with an acid in a

reactor. The reaction can be done at room temperature. However, the reaction is

exothermic, and the cooling of adiponitrile may be required, especially in high

proportions of formaldehyde.

CH2O

+ NC- (CH2) 4-CN + H2O → [-NH-CH2-NH-OC- (CH2) 4-CO-] n

Adding

water to the reaction mixture easily reduces the nylon 1,6 product, which can

be separated and washed in water to save higher purity polymer.

Like

other formaldehyde-based thermoset resins, the thermal conductivity of the polymer is a function of the CH2O / ADN ratio employed in the synthesis. Nylon

1,6 has been shown to cause high moisture absorption due to the significant concentration of >130% by weight of the polymer amide residue.

0 Comments