Nanofibers

Nanofibers

are fibers that are nanometers in diameter. Nanofibers can be taken from

different polymers and therefore have different physical properties and

possibilities of application. In some examples of natural polymers include collagen,

cellulose, silk fibroin, keratin, gelatin, and polysaccharides such as chitosan

and alginate. Polymer chains are connected by cooperative bonds. The diameters

of the nanofibers depend on the type of polymer used and the method of

production. All polymer nanofibers are unique for their large surface

area-to-volume ratio, high porosity, admirable mechanical strength, and

flexibility in operation compared to their microfiber part.

History of Nano-fiber

Nanofibers

were first produced by electron-spinning four centuries ago. Scientist Anton

Formals were the first person who attempts nanofiber production between 1934

and 1944 and published the first patent describing the experimental production

of nanofibers. In 1966, Harold Simons patented a device that could make thin

and light nanofiber fabrics with different motifs. Only in the late twentieth

century did the terms electro-spinning and nano-fiber become common among

scientists and researchers. Electro-spinning continues to develop today.

Different making methods of nanofiber

There

are several methods for making nanofibers, including drawing,

electron-spinning, self-assembling, template synthesis, and heat-induced phase

separation. The most widely used method for producing electrospinning

nanofibers are the straightforward setup, the ability to mass-produce isolated

nanofibers from different polymers, and the ability to generate ultrathin

fibers with controllable diameters, compositions, and orientations. This

flexibility allows for the control of the size and configuration of the fibers

so that a variety of structures can be fabricated for the intended application.

Properties of nanofiber

1.

Nanofibers can be generated from different polymers.

2.

It has a diameters range in nanometer.

3.

Polymer chains are connected via covalent bonds.

4.

Diameters of Nanofibers depend on the type of polymer used and the production

method.

5.

Nanofibers are unique for their large surface area-to-volume ratio.

6.

It has a high porosity.

7.

It has applicable mechanical strength.

8.

Good flexibility.

9.

Nanofibers have many possible technological and commercial applications.

Nanofibers fabrication method

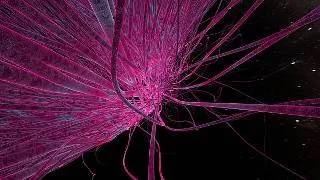

Electro-spinning

is the most widely used Nanofibers fabrication method. The instruments

necessary for electro-spinning include a high voltage supplier, a capillary

tube with a pipette or needle with a small diameter, and a metal collecting

screen. One electrode is placed in the polymer solution and the other is

connected to the electronic connector. An electric field is applied to the end

of the capillary tube that contains the polymer solution held by its surface

tension and forms a charge on the surface of the liquid. As the intensity of

the electric field increases, the hemispherical surface of the fluid at the tip

of the capillary tube elongates to form a conical shape known as the Taylor

cone. Randomly-oriented Nano-fibers are collected on the collector. Nanofibers

can also be collected in a high-end manner using special collectors such as

rolling drums, metal frames, or a two-parallel plate system. Parameters such as

jet stream movement and polymer concentration have to be controlled to produce

Nano-fibers with uniform diameters and morphologies.

Applications of Nano-fiber

i.

Nano-fiber is used in tissue engineering.

ii.

Nanofiber scaffolds are used in bone tissue engineering to mimic the natural

extracellular matrix of the bones.

iii.

Nano-fibers are under study as a possible drug carrier candidate. The

successful delivery of therapeutics to the intended target largely depends on

the choice of the drug carrier.

iv.

Surface-loaded nanofiber scaffolds are useful as adhesion barriers between

internal organs and tissues post-surgery.

v.

Nano-fiber is used in cancer diagnosis.

vi.

It is used in Lithium-air Battery making.

vii.

Quantum dots show useful optical and electrical properties, including high

optical gain and photochemical stability. A variety of quantum dots have been

successfully incorporated into polymer Nano-fibers.

viii.

Electrospun nanofibers are especially suitable for optical sensors.

ix.

It is useful for removing volatile organic compounds from the atmosphere.

x.

It can be used in masks to protect people from viruses, bacteria, fumes, dust,

allergens, and other particles.

xi.

It has the ability to separate oil-water, especially in the sorption process.

0 Comments