Introduction

Today’s fashion denim wash is done for good appearance, softness, and fashion. Modern fashion without denim doesn’t run. For color fading, rinse, enzyme, bleach, and softener wash is done and garments look attractive and fashionable.

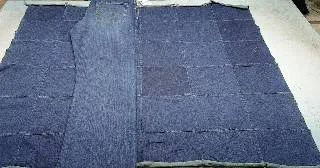

Denim wash

The wash process, which is used for denim garments to give the appearance, outlook, comfortability, and fashion of the garments is called denim wash.

Functions or objectives of garments washing –

a. To give softness to garments by using a softener needs a wash.

b. To remove size materials that are applied during fabric manufacturing need to wash and give softer need wash.

c. To introduce a fading effect in garments need a wash and result in fading or worn-out effects in the garments.

d. Giving a new fashion wash process is done on garments, bringing a different outlook (faded, color tinted, etc.), thus creating new fashion for the new generation, especially for teenagers.

e. To satisfy the consumer by washing and the wearer can use the garments after purchase satisfactorily.

How many types of denim washes

There are different types of wash done on denim garments. Such as below-

Rinse wash

Rinse wash is one of the stages for denim washing textiles. Denim un-wash garments are very rough and not comfortable to wear. At this stage, denim garments wash with detergent, anti-back staining, or other chemicals. Many times it is done with only water or softener wash. It is a short time wash of up to 20 minutes.

Recipe: For sample

Detergent- 1gm/l

Anti-back staining agent- 0.5-1gm/l

Temperature- 50°C

Time- 5-20 minutes

Then,

Fixing & softener-1gm/l (if needed)

Stonewash

Enzyme wash

Enzyme washes are very important for garments in laundry factories to get a high-low, color-fading, and worn-out look. It is an environmentally friendly wash. It involves the application of organic enzymes that eat away at the fabric, i.e., cellulose. Once the desired color is achieved, the enzyme can be turned off by changing the alkalinity of the bath or its temperature.

Effects produced by the enzyme are more noticeable in cellulose garments on the seams, hems, and pockets area. The salt paper effect is shown as the color contrast effect. Two types of enzymes are used in garments wash. Clothing washed with acid cellulose enzymes provides less color contrast than the proportion of clothing-washed neutral cellulose enzymes. The acid enzyme removes hairiness on the garment's surface and the garments load size of the machine is 60-70 Kg jeans per machine and it cannot be overloaded.

Recipe: For sample

Detergent- 1gm/l

Anti-back staining agent- 0.5-1gm/l

Enzyme- 1-2gm/l

Pumice stone- 5-10Kg (if needed)

Temperature- 45°C

Time-up to effect achieving

Bleach wash

Bleach wash is one of the stages in the manufacture of the textiles denim industry. Bleaches work by reacting with many colored organic compounds like natural dyes and converting them into colorless dyes. While most bleaches are oxidizing agents, some are reducing agents. Bleaching agents that do not contain chlorine are usually made based on peroxides such as hydrogen peroxide, sodium percarbonate, and sodium perborate. These bleaches are called 'non-chlorine bleach,' 'oxygen bleach', or 'color-safe bleach. There are niche uses for bleach reduction, such as sulfur dioxide used to bleach wool, either as a gas or from a solution of sodium dithionite and sodium borohydride.

Bleaches usually react with many organic substances in addition to the intended pigment, so they can weaken or damage natural materials such as fibers, fabrics, and leather, and intentionally apply a dye like the indigo of denim. For the same reason, eating products, breathing in smoke, or contact with the skin or eyes can cause health damage.

Recipe: For sample

Bleach- up to shade

Temperature- 45-50°C

Time- up to shade achieving

Acid wash

The name acid wash is related to the acids used for this type in older recipes. In modern methods, it is done by oxidation. The use of bleach or oxidative is very safe and economical in comparison to acid. Different chemicals are used and among them, potassium permanganate (KMnO4) and phosphoric acid are mainly used.

Acid wash is basically done by soaking pumice stone in hypochlorite. Sometimes KMnO4 is used instead of bleach. The selection of oxidant is very important and mainly depends on the type of fabric. When it is done with a pumice stone the washer and garments should not contain any water. Dry garments are much more suitable for this process than damp ones. Pumice stone is soaked in bleach and left to open for a little time so they get only damp rather than wet. Then they are processed in a machine with garments. The extent of the effect is controlled with process time, the concentration of oxidant solution, and the quantitative ratio of a garment to stone.

In some derivatives of this process cotton balls or cotton or foam balls, ribbons are used instead of pumice stone. The impact of cotton is very different from pumice stone. It produces a more merged and cloudy effect. Cotton towels are sometimes used for this effect to produce more cloudy effects on garments. Black Sulpher is not processed able with bleach as sulfur reacts vigorously with sulfur and the pace of the process cannot be controlled.

Recipe: For sample

Potassium permanganate/Japanese bleach- up to shade(gm/l)

Pumice stone/cotton ball/foam ball/towel/cork sheet, etc. (Condition of shade)

Time- up to shade achieving

Tie wash

In denim wash, tie wash is a variety of wash, here garments are tied with ribbon/rope/cable for achieving vein effects. It is a fancy type of wash that is done for customer attraction. The wash process is done up to achieve effects.

Softener wash

A fabric softener is a conditioner that is basically applied to laundry during the rinse cycle in a washing machine. Unlike laundry detergents, fabric softeners can be considered laundry aid after treatment.

Machine washing puts a lot of mechanical stress on textiles, especially natural fibers such as cotton and wool. The fibers on the fabric surface squash and burn and make the laundry feel stiff when air-dried. Adding a liquid fabric softener to the final rinse results in a laundry that feels softer.

Fabric softeners cover the surface of a fabric with chemical compounds that are electrically charged, causing the threads to rise from the surface and give a soft and fluffy texture. Cationic softeners are bound by negatively attracted electrons to negatively charged groups on the surface of the fibers and neutralize their charge. The long aliphatic chains then move to the outside of the fiber, giving off oiliness.

Recipe: For sample

Softener- 1-2gm/l

Temperature- 45-50°C

Time- 5-10 minutes

Conclusion

There are also many more washes, which are done in the laundry industry. These are resin wash, foam wash, rubber ball wash, air polishing, etc. different types of washes are done for different reasons.

0 Comments