Introduction

After

100 years, the total world is experiencing another pandemic disease caused by

the COVID-19 virus in 2020. Still now almost in 199 countries, this virus has

been found. Some countries are deadly suffering like the USA, Italy, Spain,

Iran, China, the UK, etc. Commonly all affected countries are sufferings from

inadequate medical safety gear. The doctors need to wear Personal Protective

Equipment (PPE), Disposal gloves, and Masks for the treatment of corona-affected

people. But unfortunately, all are at life risk due to a shortage of these

pieces of equipment. Thus, the epidemic created opportunities for textile and

garment manufacturing to meet the global demand for medical textiles for the

Bangladesh textile and garment industry. Already Bangladesh has proved that it

can grab the segment.

|

| COVID-19 PROTECTION |

Medical Textile

Medical

textiles also known as bio-medical textiles is a combination of textile

technology and medical science. The main purpose of medical textiles is to

improve human health and well-being. The main functions of medical textiles are

healthcare, hygiene, new fiber technology, and synthetic medical textile

products. The medical textile is a fast-growing sector for its demand.

Definition of Medical Textile

The combination of textile technology and medical sciences has resulted in a new field called Medical Textiles. The new areas of application for medical textiles have been identified with the development of new fibers and manufacturing technologies for yarns and fabrics. Development in the field of textiles either natural or man-made textiles is normally aimed at how they enhance the comfort of the users. The development of medical textiles can be considered as one such development, which is really meant for converting the painful days of a patient into comfortable days.Types of fabric used in medical textile

Different

types of fabrics are used in medical textiles. But mainly four types of fabrics

are mostly used in medical textiles. These are-

1.

Woven

2.

Non-woven

3.

Braided

4.

Knitted

The properties of the medical textile are as follows-

a.

Medical textiles must be non-toxic and non-allergenic.

b.

It must be compatible with most living systems.

c.

It should be sterilized without imparting any change in physical and chemical

characteristics.

d.

If necessary, it should be versatile in its physical form like powder form,

aqueous form, film, fiber, sponges, etc.

e.

It should have enough lightness, strength, elasticity, softness, etc.

Nano-technology in medical textile

Nanotechnology

has gained tremendous popularity over the past decade. Nano-fiber-based

products, as well as nano-coated materials, are innovations in medicine so, in

our technical poster, we are going through the latest medical textile,

nano-based products due to the following features and wide applications.

Nanofibers are very attractive due to their unique properties, the high surface

area of volume ratio, the thinness of the film, the porosity of nanoscale fiber diameter structure, and their lightweight.

Nanofibres can be perforated and the pore size distribution can be wide, so

they can be considered as engineered scaffolding with wide application in the

field of tissue engineering. Some other applications such as wound dressings,

bone regeneration, and nanofibers can be carriers of various drugs at specific

sites, etc.

Smart medical fabric technology

Smart

medical textiles revolutionize healthcare. Smart fabric technology has a great

job of monitoring patients. The sensors integrated into the right of the

textile provide the least annoying way to monitor the vitreous. Patients ’body

temperature can be controlled by a fabric that can identify the wearer and the

ideal body temperature requirements. This fabric was designed by the VTT

Technical Research Center in Finland. It works by identifying the patient and

measuring the ambient temperature and then adjusting the temperature according

to the patient’s needs. This can be especially beneficial for hospital patients

who feel cold after surgery or become very hot during the operation. Users can

access lab-quality analysis using the biometric "shirt" developed by

Hexoskin. Several projects are being developed, such as clothes for measuring

heart rate, blood transfusions from textiles, and suits for children with

disabilities. New opportunities are created in the healthcare sector using new

and smart textiles for medical applications.

Medical textile product-

a.

Wound care,

b.

Bandages,

c.

Adult diapers,

d.

Aprons,

e.

artificial ligaments,

f.

Artificial lung,

g.

artificial skin,

h.

Artificial tendon,

i.

Artificial vascular grafts,

j.

Artificial cornea,

k.

Artificial heart,

l.

Artificial heart valves,

m.

Artificial joints,

n.

Artificial kidney,

o.

Baby diaper,

p.

Bandages,

q.

Contact lenses,

r.

Gauze,

s.

Gowns,

t.

Masks,

u.

Plasters,

v.

Sanitary napkins,

w.

Medical gloves,

x.

Surgical caps etc.

Human textile

Human

textiles are used to replace damaged parts of the human body. Another purpose

of this is that after repairing the body with the help of an artificial thread,

the body considers it as an external part but when the damaged part is filled

with thread made from human cells, it easily absorbs the body and does not

cause any internal problem.

Extracorporeal device

An extracorporeal device is a mechanical organ. An extracorporeal device like

artificial cleansing, artificial kidney, artificial liver, etc. Modern textile

technology plays an important role in creating an extracorporeal device.

Implantable material

This type of material is used to repair the body. It is used to remove damaged

organs by creating artificial limbs. There are two types of implantable

material.

a. Soft tissue Implant

b. Hard tissue Implant

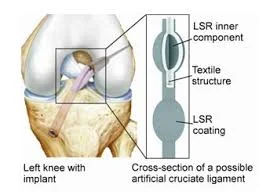

Artificial ligaments

This medical device is used to attach the two ends of the bones. It is possible to

create Artificial Ligaments using polyester such as Man Made fibers. The usage

of the ligament varies based on the type of operation. The artificial ligaments

are normally subject to a lot of wear and tear. They also carry a risk of

septic arthritis.

|

| ARTIFICIAL LIGAMENT |

Contact lenses

Contact

lenses are one of the most used textile technologies in modern times. Contact

Lenses change the color of the eyes and make them sweeter. It is made with

water-absorbing material.

|

| CONTACT LENSE |

Artificial cornea

This

technology is used to remove blindness. Textile materials used in this field

should be flexible and have sufficient mechanical strength.

Artificial kidney

Hollow

viscose and polyester are used to make it. An artificial kidney is used to remove

waste from the blood.

Mechanical lung

It

removes carbon dioxide from the blood and helps in transporting clean oxygen.

It is used in hollow viscose to create.

The global market of medical textile

The

global medical textiles market was valued at USD 16,686.6 million in 2019 and

is projected to reach USD 23.3 billion at a CAGR of 4.9% by 2025, according to

a new report conducted by Grand View Research, Inc. Now the US revenue of the

medical textile industry is expected to grow at a rate of 5.3% during the

forecast period. Also, Germany's medical textiles market was valued at USD

1,852.1 million in 2019 and is projected to grow significantly over the

forecast period. And the Chinese market is anticipated to reach USD 1,547.4

million by 2025.

|

| Medical Product |

Opportunity for Bangladesh in the field of medical textiles

Bangladesh

is the most populous country in the world with a huge requirement for

healthcare services. Consumption is increasing rapidly. Healthcare spending

from the private sector comprises over 70% of the market which is more than

comparable developing countries as well as developed countries. The Coronavirus

impact has revealed the weakness and vacuum of medical safety kits all over the

world. Here the Bangladeshi manufacturers can think over it and can take this

as an opportunity for the long run. Regular fashion brands are canceling their

orders, and at the same time, PPE demand growing sky-high all over the world. So,

factories can immediately manufacture this demand-based PPE and also can-do plans

for future business. Right now there are a few manufacturers who are supplying

medical accessories to several countries.

Medical

textile manufacturers in Bangladesh

1.

Smart Group of Industries

2.

Nasir & Sons Bangladesh

3.

E-Baik Transport Corporation

4.

Abhiyan International

5.

Sagar Trader's

These

manufacturers of Bangladesh supplying regularly their products in many

countries such as the USA, Malaysia, Pakistan, India, Lebanon, Sri Lanka, and

Nigeria. There are now many more factories like Snowtex, Urmi Group, Aman

Group, Dekko Group, etc. that are producing personal protective equipment (PPE)

to meet the current local demand.

0 Comments