What is 3D printing?

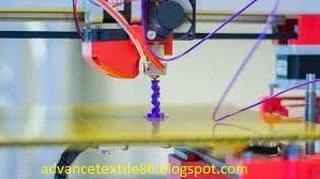

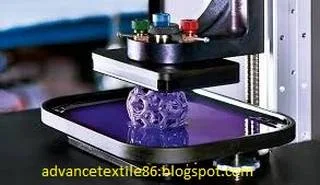

3D

printing is the creation of three-dimensional objects from the CAD model or

digital 3D model. The term 3D printing refers to the various processes in which

elements are joined together, deposited, joined, or solidified under computer

control to create a three-dimensional object. One of the major advantages of 3D

printing is the ability to create very complex shapes or geometries that would

otherwise be impossible to create by hand, including fused deposit modeling or

FDM blanks or parts of internal truss structures, the most common weight loss

3D printing process by 2020.

History of 3D printing

The

general concept and method for use in 3D printing were first described by

Raymond F. Jones in 1950. In 1974, David E. H. Jones put the idea of 3D

printing in his regular column Ariadne in the New Scientist Journal. In The 1980s, 3D printing techniques were considered suitable only for creating

functional or aesthetic prototypes, and at the time the more appropriate term

for it was rapid prototyping.

American

entrepreneur Bill Masters filed a patent for his computer automated

manufacturing process and system on July 2, 1984. This filing is on record at

USPTO is the first 3D printing patent in history. It was the first of three

patents to be included in the Masters, which laid the foundation for the 3D

printing system used today. Early 1993 saw the launch of Sanders Prototype,

Inc. and later an inkjet 3D printer company called Solidscape, introducing a

high-precision polymer jet fabrication system with a soluble support structure.

In the early 2010s, 3D printing, and additive manufacturing conditions developed

sensations in which they were an alternative umbrella term for additive

technology, one being used in the consumer language and media popular language

and the other more formally used by industrialists, part manufacturers, machine

manufacturers, and global technical standards companies.

In

2014, Benjamin S. Cook and Manas M. Tentjaris demonstrated the first

multi-material, vertically integrated electronics additive manufacturing platform that enables 3D printing of electronics operating at up to 40 GHz.

Peter Zelinski, chief-in-chief of Additive Manufacturing Magazine, noted in

2017 that the terms are still often synonymous with casual use, but some

manufacturing industry experts are trying to make a distinction between

additive manufacturing 3D printing plus other technologies or a manufacturing

process.

Objectives of 3D printing

3D

printing revolutionized the way products were made. It is widely used for

ideals, imagining product design with a model in hand. It is possible to create

functional models, which make it easier for designers and engineers to verify

product designs and identifies flaws that would otherwise not be noticed in

virtual simulation and analysis, especially design flaws related to fit, form,

and ergonomics. With a wide range of materials in a variety of colors,

companies can now create models that are surprisingly close to the original or

final product.

Applications of 3D printing

3D

printing has developed significantly and can now play an important role in many

applications, the most important of which are manufacturing, medicine, architecture,

custom art, and design. Such as below-

Manufacturing applications of 3D printing

The

earliest applications of additive manufacturing are at the end of the tool room

of the production spectrum. For example, rapid prototyping was one of the

earliest additive variants and aimed to reduce the lead time and cost of

developing new parts and prototypes of devices, which had previously only been

done in subtractive toolroom methods such as CNC milling and turning. Less than

0.00005 Better quality parts made faster, but sometimes too expensive for

prototype parts of less precision. World, assembling methods are creative and

sometimes unexpectedly moving towards the end of production which was

previously the only province of the subtractive method in some cases now Can

also be made more profitable. Also, new developments allow RepRap

technology to produce the same device by magnetic switching both additive and

subtractive mounting tool heads.

Medical applications of 3D printing

The

surgical use of 3D printing-centric therapy began in history in the mid-1990s

with physical modeling for bone reconstructive surgical treatment plans.

Surgeons were more prepared by practicing sensitive models before surgery and

patients were better cared for. Patient-matched implants were a natural extension

of this work, allowing truly personalized implants to fit a unique individual.

Virtual plans for surgery and direction using 3D-printed, personalized

instruments have been effectively applied in many areas of surgery, including

complete joint replacement and craniomaxillofacial reconstruction. Further

study of models for heart and solid organ surgery planning has increased use in

this region. Hospital-based 3D printing is now a matter of great interest and

various organizations are trying to combine this specialty between individual

radiology departments. The technology is unique for rare illnesses, being used

to create patient-matched devices. An example of this is the bioresorbable

tracheal splint for the treatment of newborns with tracheobronchomalacia

developed at the University of Michigan. Several device manufacturers have

begun using 3D printing for patient-matched surgical guides. The use of

additive manufacturing for the serialized production of orthopedic implants is

also on the rise with the ability to efficiently create perforated surface

structures that facilitate redundancy. Printed casts for broken bones can be

custom-fitted and illuminated, allowing the wearer to scratch any itch, wash

the injured area, and ventilate. These can also be recyclable.

Industrial applications of 3D printing

3D

printing has entered the world of clothing experimentally with fashion

designers experimenting with 3D-printed bikinis, shoes, and clothing. In

commercial production, Nike used 3D Vapor laser talon football shoes for American

football players and 3D production custom-fit shoe prototypes for 3D production

for New Balance athletes and 3D printing. It has reached a stage where companies

are printing customer-grade eyewear with on-demand custom fit and styling.

On-demand customization of glasses is possible through rapid prototyping.

However,

academic circles have commented on the potential limitations of human

acceptance of such mass-customized clothing items due to the potential decline

in brand value communication.

In

the world of high fashion courtiers like Karl Lagerfeld Design for Chanel, Iris

Van Harpen, and Noa Raviv, who have worked on stratification technology, have

hired and featured 3D printing in their collections. Picks from their lines and

other works with 3D printing were on display at the 2016 Metropolitan Museum of

Art Anna Wintour Costume Center at the Manus X Machina exhibition.

Sociocultural applications of 3D printing

With the launch of the Open Source RepRap and Fab@Home project in 2005, a rapidly expanding hobby and home use market was established. The technical lessons of virtually all home-use 3D printers are in the ongoing RepRap project and related open-source software initiatives. In the case of distributed manufacturing, a study found that 3D printing can be a common market product that enables consumers to save money related to the purchase of common household goods. For example, instead of going to the store to buy something made in the factory by injection molding, a person can print it at home from a downloaded 3D model instead.

0 Comments