Moisture

All

textiles are hygroscopic i.e. they absorb or release moisture depending on the

relative humidity of the surrounding air. If the atmosphere is drier than the

relative humidity of the textile, the textile will release moisture from the

air. If the air is too humid then the humidity of the textile will increase.

This moisture loss and gain occur at every stage from the initial processing of

the fiber to the final garment production, distribution, and use by the

consumer.

Moisture

is measured as “relative humidity”. This is defined as the amount of water in

an air sample compared to the maximum amount of water that can hold air at the

same specific temperature. It is expressed in the form of 0 to 100%.

Cold

air can retain less humidity than warm air so air humidity is “relative” to its

temperature. For example, a sample of air at 10°C may retain less humidity than the

same sample of air at 20°C.

Although both samples contain the same amount of water, the relative humidity

of the warm sample is lower because it may contain more moisture than the cold

air sample. This means that the humidity of the indoor air can be lower even in

humid weather when the cool moist air from outside enters a textile

manufacturing facility and its temperature rises. A 20°C temperature

increase can lead to a normal drop in the humidity of about 60% RH (relative

humidity). This means that the humid air entering a building at 80% RH will

become only 20% RH when heated. This can cause big problems in textile

production.

Moisture Regain

Moisture

regain is defined as the percentage of water present in a textile material of

oven-dry weight. The percentage of moisture in a textile material brought into

equilibrium with a standard atmosphere after partial drying, calculated as a percentage

of the moisture-free weight.

Say,

Oven

dry weight = D

Weight

of water = W = Original weight - oven-dry weight

Moisture

Regain = MR or R

Then,

R (%) = 100 W/ D

Moisture Content

The

moisture content is the amount of moisture in a material when expressed as a

percentage of the total weight is known as the percentage. It is defined as The weight of water in the material is expressed as a percentage of the total weight.

Say,

Oven

dry weight = D

Weight

of water = W = Original weight- oven-dry weight

Moisture

Content = MC or C

Then,

C (%) = 100 W/ (W + D)

Relation Between moisture regain and moisture content

Say,

Oven

dry weight = D

Weight

of water = W

Regain

= R

Moisture

content = C

For

moisture regain

R=

100W/D............ (1)

For

moisture content

C=

100W/ (D + W).......... (2)

From

equation (1)

D=

100W/R

From

equation (2)

C=

100W/ (100W/R + W)

C=

100/ (100/R + 1)

C=

100R/ (100 + R)

100R=

100C + RC

R=

100C/ (100-C)……… (3)

Equation

(3) explain the relationship between moisture regain and moisture content.

Factors affecting the moisture regain of textile fibers

Different

fibers absorb different amounts of moisture depending on their affection for

water. There are various factors that affect the return of moisture to textile

materials, such as;

1.

Relative humidity

2.

Time

3.

Temperature

4.

Previous history of the sample

Relative humidity

The

relative humidity of an air-water mixture is defined as the ratio of the partial pressure of water vapor in the mixture to the equilibrium vapor the pressure of water at the surface of pure water at a certain temperature:

Relative

humidity = partial pressure of water vapor/equilibrium vapor pressure of water

In other words, relative humidity is the ratio of how much water vapor is in the

air and how much water vapor it can hold at a potential temperature. This

varies with air temperature: cold air may contain less vapor, so water vapor

may condense when some air is cooled. Similarly, warming some foggy air can

cause fog to evaporate, as the air in the water droplets is able to retain

water vapor. So, changes in air temperature can change relative humidity, even

when absolute humidity remains constant.

Relative

humidity only considers invisible water vapor. Mist, cloud, fog, and water

aerosols do not count for measuring the relative humidity of the air, although

their presence gives an indication that a body of air may be near the dew

point.

The relative humidity is usually expressed as a percentage; A higher percentage

means the air-water mixture is more humid. At 100% relative humidity, the air

is saturated and at its dew point.

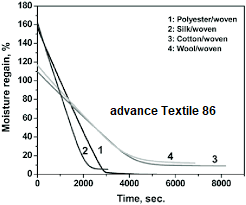

Time

It

takes a certain amount of time to reach a new equilibrium at a certain relative

humidity, which is then transferred to the atmosphere with different relative

humidity. The time depends on the physical appearance of the material and how

easily moisture can reach or escape from the individual fibers. For example,

the British standard for yarn count testing offers one hour for yarn in the

form of hanks to achieve compatibility, but three hours for yarn in the

package.

Temperature

Temperature is a measure of warmth or coolness expressed on any one of the different scales, including Fahrenheit and Celsius. Temperature indicates that heat energy will flow spontaneously from a hot body to a cold body. The effect of temperature on moisture regain is not important. A change of 10°C will bring about a 0.3 percent change in cotton moisture regain. This effect can be ignored. Now we can say that for practical purposes the temperature does not affect the moisture regain of a sample.

The previous history of the sample

The previous history of the sample may affect the regain of balance. In the case of

the hysteresis effect, the recovery value of the wet sample is higher than that

of the dry sample of equilibrium. Processing recovery can also change. Removal

of oil, wax and other impurities also changes the recovery. For example, formal

regain of scoured wool is 16% and oil-combed tops are 19%.

Different fibers moisture regain & content (%)

Different

fibers moisture regain & content (%) are below-

Textile Fiber Moisture Regain

(MR%) Moisture Content (MC%)

Cotton

8.5 7.34

Jute 13.75 12.1

Viscose 11.0 9.91

Silk 11.0 9.91

Wool 16.0 13.8

Acrylic 1.5 0

Flax 12.4 10.4

Hemp 12.4 10.4

Acetate 6.0 0

Polyester 0.4 0

Nylon 4.0 3.1

Azlon 10

Metalic 0

Triacetate 3.5

Rubber 0

Wool

yarn 18.25

Glass

0

Moisture level for different fiber

In

terms of performance, natural fibers are much more sensitive to moisture than

man-made ones. However man-made garments suffer more from static charge

build-up.

Cotton

and linen have to be processed at very high levels, about 70-80% RH because

they are very fragile. By wetting every process from raw material combing to

carding, twisting, spinning, and weaving, the manufacturer can ensure that the

product remains flexible and prevents breakage. The longer the fiber, the finer

it can cut.

Wool is similarly sensitive to dry air, although a little more forgiving, requiring a moisture level of about 65% RH. Man-made fibers below 45% RH require accurate, although low, moisture levels, they are prone to generating static electricity. Silk should be processed between 65-70% RH, although artificial silk spinning requires a high level of 85% RH.

0 Comments