Textile waste

Textile

waste disposal is crucial for the global textile industry. Tons of textile products are discarded by consumers and end up in landfills around the world.

Estimates say that a vast majority, such as 95 percent of discarded products,

can, in fact, be re-worn, reused, or recycled, depending on their condition.

Indeed, the situation is pushing the trend, because, as natural resources are

limited and the cost of waste removal is increasing, more and more waste is

being recycled or reused.

Textile

waste is produced through a number of streams, including the fiber, textile,

and garment manufacturing industries, the consumer, and the commercial and

service industries. CTR classifies textile recyclable materials as pre or

post-consumer waste.

According

to the US Environmental Protection Agency (USEPA), about 5% of all landfill

space is textile waste; However, recycled post-consumer textile waste is only

15% per year, and thus, a huge 85% of the waste ends up in landfills. Some

organizations, including the Council for Textile Recycling (CTR), are working

to raise awareness about keeping post-consumer textile waste out of solid waste

streams with a view to reaching zero textile waste levels by 2037.

According

to the CTR, pre-consumer textile waste is the processing of waste produced

during the processing and production of finished yarns and textiles, technical

textiles, nonwoven, garments, and footwear, including offcut, selvage,

shearing, discarded materials, and/or B-grade garments. Pre-consumer textile

waste is generally considered "clean waste". Pre-Consumer Textile

Waste is produced by the original manufacturers and is never made for the

consumers.

Postconsumer

textile waste refers to textile products that the consumer disposes of for

whatever reason they can longer be run or are not liked by consumers. In general,

post-consumer textile waste is of good quality, which can be reused or recovered

as second-hand clothing and is usually sold in poorer regions of the world. Even

textile products that will probably not be used by consumers can potentially be

cut into fibers for reuse for production.

Textile waste recycling

Recycling

and recovery of textile products such as glass, metal, plastic, and paper and

product groups such as electronics, packaging, and automotive is not uncommon.

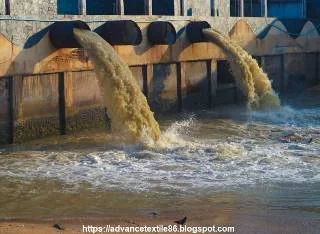

Recycling activities related to the textile sector mainly focus on the

treatment of chemical waste and contaminated water - problems that occur during

the manufacturing process. The number of scientific or practical studies on

solid waste recycling is extremely limited.

Waste

generated by the textile sector contributes to land, water, and air pollution.

Perishable textiles generate greenhouse gases and thus pollute the air. Huge

amounts of chemicals used to produce textile products inevitably pollute

rivers. And discarded textile products fill landfills, which are already

scarce. All of this waste is an asset that could be used to make value-added

products. Not only is this possibility wasted, but more raw materials have to

be used, resulting in more energy consumption.

Recyclable technologies are divided into primary, secondary, tertiary, and quaternary methods and all four of these methods are applicable to fiber recycling. Early approaches refer to the recycling process as it was originally. Secondary recycling means melting a plastic product into low-quality processing but still a new one. Tertiary recycling refers to the processes that convert plastic waste into basic chemicals or fuels, such as pyrolysis and hydrolysis. Quaternary recycling involves burning fibrous solid waste and converting the heat generated by the fuel into a source of energy.

The

most recycled textile waste is thermoplastic polymer-based fibers because they

are easy to process and can be given different shapes and sizes later. Yet,

natural fibers such as cotton, wool, and silk are also finding their way into

recycling streams through downcycling or upcycling. Textile recycling is not a

widespread industry today. The number of companies providing textile fiber

recycling services is limited because it is not economically viable and is not

technologically advanced. The lack of technological innovation and the constant

supply of cheap fabrics in the market hinder the motivation to apply research,

development, and recycling strategies; However, this does not completely hinder

the development of new technologies for recycling textile waste. Soon, some

obstacles will have to be faced and addressed to further increase the recycling

of textile waste. In the case of technology, the fundamental question is the

fiber composition of textile materials. Current garments in today’s market are

more varied in terms of design and fiber content than in the past. Other

compounding factors are problems/difficulties in separating composite

materials, separation efficiency, quality of separated material, and hence the

quality of recycled material, etc. Since recycled fibers and fabrics still

provide lower levels of quality, virgin natural and synthetic fibers remain

popular alternatives. There are some reusable technologies on the market today.

Clearly,

recycling is not always the preferred approach, when not only the environmental

context but also the competition of the final product in the market is taken into

consideration. Existing recyclable technologies need to be better, cleaner,

more energy-efficient, and less expensive. Textile recycling, a key concept for

sustainability, is currently facing barriers related to cost, time, and

technology.

Textile waste environmental impact

In addition to increasing the efficiency of recycling methods and processes, the market for recyclable products should increase. In short, more encouragement is needed for recycling, wherever it is economically and technically possible. Textile recycling has important advantages, both environmental and economic. This reduces the need for landfill space, the use of already rare virgin resources, pollution as well as water and energy costs, and the demand for paint and fixing agents. However, although recycling provides a way to reduce the negative environmental impact, it is not without some problems.

Unstable

use of textile products ensures the deterioration of the environment. In order

to achieve environmental integrity and sustainability, it is not enough to

encourage textile companies to produce more environmentally friendly products.

In this context, Connolly and Prothero write: "Instead of focusing on

whether green can serve as a strategy, we should probably try to understand

more about the process that has forced people to believe that they, as

individuals, can help solve global environmental problems."

Conclusion

Therefore,

recycling waste from the textile industry is very important. The future of

textile recycling depends largely on gaining more experience and a foundation for

its implementation and more innovative approaches in the industry. Clothing

retailers are key actors on this front, as they are uniquely able to influence

and improve consumer attitudes toward sustainability. Clothing retailers are

not only likely to influence consumer decisions, but they are also in a

position to change the way they use them. People can learn the importance of

reuse as well as reuse and resale with the help of companies and it is not

limited to developing countries. Through such actions, consumer awareness about

sustainable costs will increase, which will lead to less environmental damage

in the future.

0 Comments